Documentation

Welcome to the Tufting Equipment Documentation page, your comprehensive guide to the maintenance and operation of tufting equipment essential for creating stunning rugs and carpets. Here, you'll find detailed instructions and insights into the care and usage of the Tufting Gun 2-1 Cut and Loop (AK-1), Tufting Gun - Loop (AK-2), Rug Trimmer, and Flat Shearing Machine.

This page is currently under development!

-

Tufting gun - 2 in 1 Cut and Loop (AK-V) documentation

Tufting gun - 2 in 1 Cut and Loop (AK-V) documentation

-

Tufting gun - 2 in 1 Cut and Loop (AK-1) documentation

Tufting gun - 2 in 1 Cut and Loop (AK-1) documentation

-

Tufting gun - loop (AK-2) documentation

Tufting gun - loop (AK-2) documentation

-

Rug trimmer documentation

Rug trimmer documentation

-

Flat shearing machine documentation

Flat shearing machine documentation

Maintaining your tufting gun is essential for ensuring its longevity and consistent performance. Regular maintenance not only keeps your machine running smoothly but also helps you achieve high-quality tufts in your projects. This article provides detailed guidelines on choosing the right oil, applying it correctly, and performing essential maintenance tasks for your tufting gun, specifically focusing on the AK-5 model. Why Maintenance Matters Proper maintenance of your tufting gun ensures that it operates at peak efficiency, reducing the risk of breakdowns and extending its lifespan. A well-maintained tufting gun delivers consistent results, allowing you to create beautiful rugs and carpets with ease. The maintenance of a tufting gun c...

The AK-V tufting gun has quickly gained popularity among crafters and professionals for its innovative design and dual-function capabilities, allowing users to create both cut and loop pile with ease. However, as with any new product, a few minor issues have surfaced. One of the most common problems that some AK-V users have encountered is the AK-V tufting gun auto-firing and sewing even when the trigger is not pressed. This issue, though inconvenient, is thankfully easy to resolve. Understanding the Auto-Firing Issue The AK-V tufting gun auto-firing problem typically presents itself as follows: when the power switch is turned on, the gun starts sewing and firing on its own, without any input from the user. This can be both alarming and f...

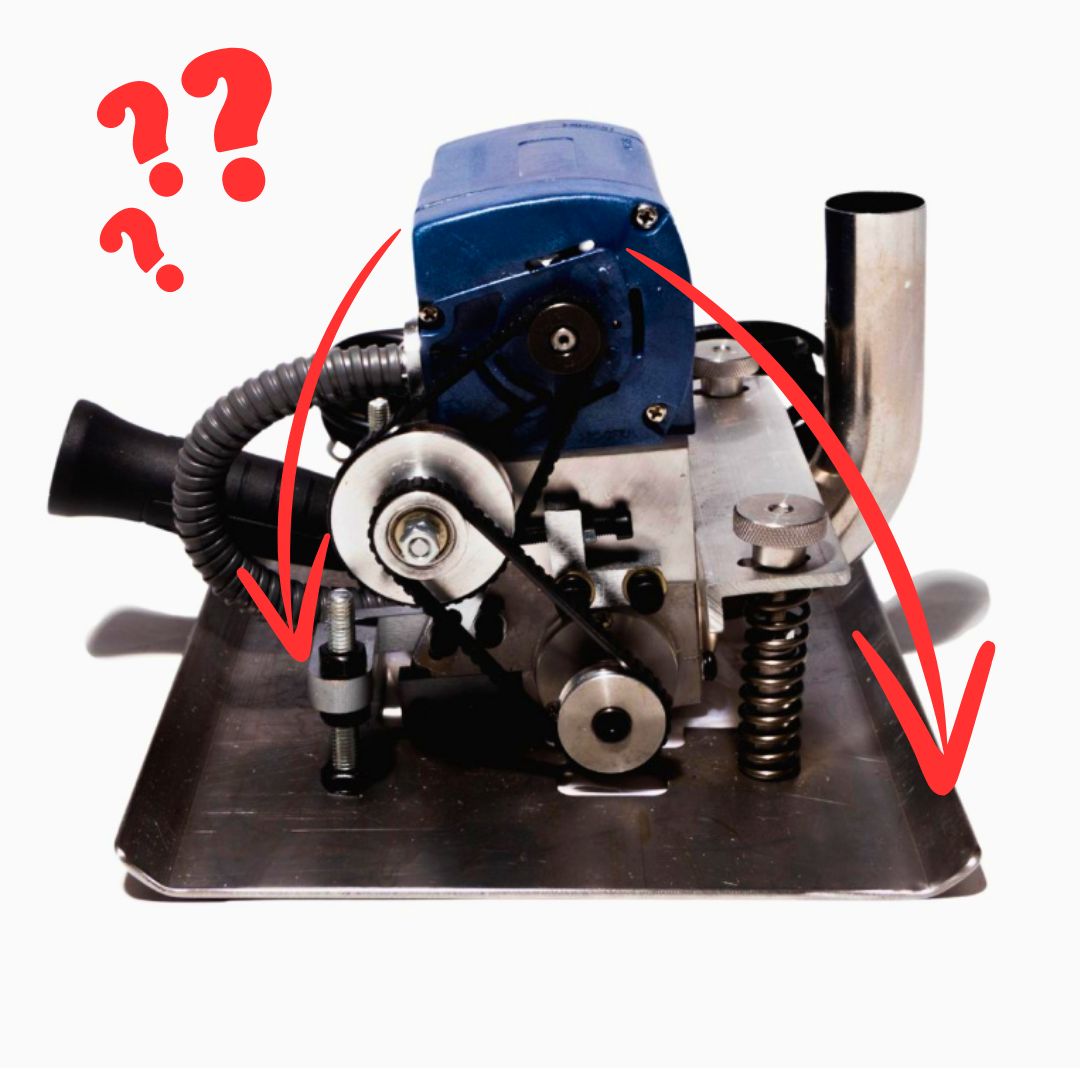

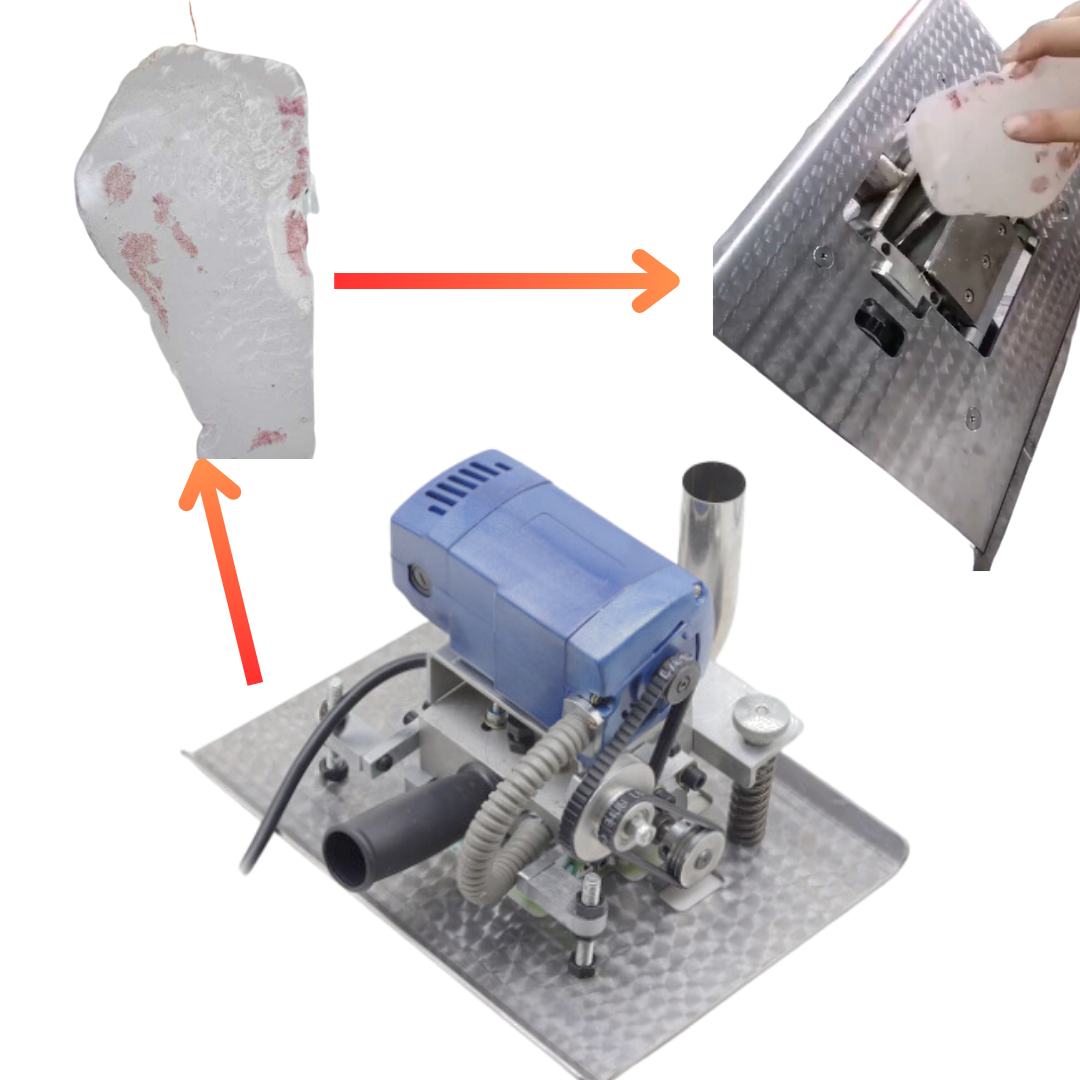

The flat shearing machine for rugs is a game-changer in the world of carpet finishing. Its ability to deliver a uniform, clean cut across the surface of rugs and carpets has made it a preferred tool for professionals in the industry. This machine drastically reduces the time and effort required to finish rugs, ensuring a high-quality result with every use. In this guide, we will not only highlight the benefits of this remarkable tool but also provide step-by-step instructions on how to adjust the cut height, ensuring you get the perfect trim every time. Proper height adjustment is crucial for achieving consistent results and avoiding potential mishaps, especially when working near the edges of your rug. What Makes the Flat Shearing Machin...

What Oil Should You Use on Your Tufting Gun? When it comes to maintaining your tufting gun, proper lubrication is crucial for smooth operation and to prevent overheating. Here’s a straightforward guide on choosing and applying the right oil. Best Oils for Your Tufting Gun: Sewing Machine Oil: This is the top recommendation due to its light viscosity and ability to keep your machine running smoothly without leaving residue. One of the most premium sewing oils is our Eurol® Oil. WD40: Cheap options that basically makes the work done, but sewing machine oil is better for regular maintenance because it’s specifically designed for mechanisms like those in tufting guns. Both options are correct choices for oiling a tufting gun. Addi...

As a proud owner of a flat shearing machine, it's important to ensure that it remains in top-notch condition to deliver consistent and efficient results. Proper maintenance not only prolongs the life of the machine but also guarantees the quality of the finished products. Here are some essential maintenance tips straight from the factory that will keep your flat shearing machine in prime working condition. Blade Maintenance Regular maintenance of the blades is crucial for optimal performance. After each use, it is recommended to clean the blades to remove any residual hairs or debris that may have accumulated. This can be done by gently blowing out any floating hairs from the blades using compressed air. Additionally, if you notice that t...

Proper maintenance of your rug trimmer is essential to ensure its longevity and optimal performance. Follow these guidelines to keep your rug trimmer in top condition: Regular Cleaning: After each use, clean the blades and cutting area of the rug trimmer to remove any accumulated yarn fibers, dust, or debris. Use a soft brush or cloth to wipe down the surfaces, ensuring smooth operation and preventing clogs and friction. Lubrication: Apply a small amount of lubricating oil to the moving parts of the rug trimmer, such as the blade and trimmer to trimmer head contact points (check picture bellow showing what to oil). This helps reduce friction and ensures smooth movement during operation. Be sure to use a lubricant suitable ...

By following these maintenance guidelines, you can ensure that your tufting gun remains in optimal condition, delivering high-quality tufts consistently. Proper care and attention will extend the life of your equipment, allowing you to create beautiful rugs and carpets for years to come. Tufting gun maintenance is dived into 3 important sections to follow. Basic Maintenance Proper maintenance of your tufting gun is crucial for its longevity and optimal performance. Here are some fundamental steps to keep your machine in top condition: Regular Cleaning: Dust and debris can accumulate in the moving parts of the machine, affecting its functionality. Use a soft cloth or brush to remove any buildup and ensure smooth operation. Check ...